- Expertise

- Infrastructure

Ports

Shipping terminals are a crucial component of many projects. In many cases they involve interfacing with the port authorities and other third-party terminal users, which can become complex where terminals are already in operation. Sedgman Novopro can become a valued asset in structuring and organizing workflows, communications, etc. with all stakeholders to integrate a feasible solution of a specific project design into shared infrastructure utilization.

Sedgman Novopro also possesses the capability to design “Green field” terminals, which can involve various components on an as-required basis. They can include the following:

- Storage facilities

- Feed/delivery and reclaim systems

- On-site utilities

- Water and waste treatment

- Tie-ins with the existing material handling systems and/or utilities

All elements are tailor designed to fit given project specifics, such as tonnage level of automation versus initial capital expenditure, future expansions, and modularization. For additional details, please visit "Bulk Material Handling & Storgage" portal of our website.

Bulk Material Handling & Storage

Over the years, Sedgman Novopro has gained much in-house know-how on bulk materials storage and handling from involvement in a number of mining and industrial projects worldwide. In all of their phases, every project requires storage provisions and the associated material handling equipment for plant or unit operations buffering. In order to fulfil these aspects, the engineers at Sedgman Novopro in conjunction with associated experts in the field, have provided our clients with complete material storage solutions catered to each project-specific application.

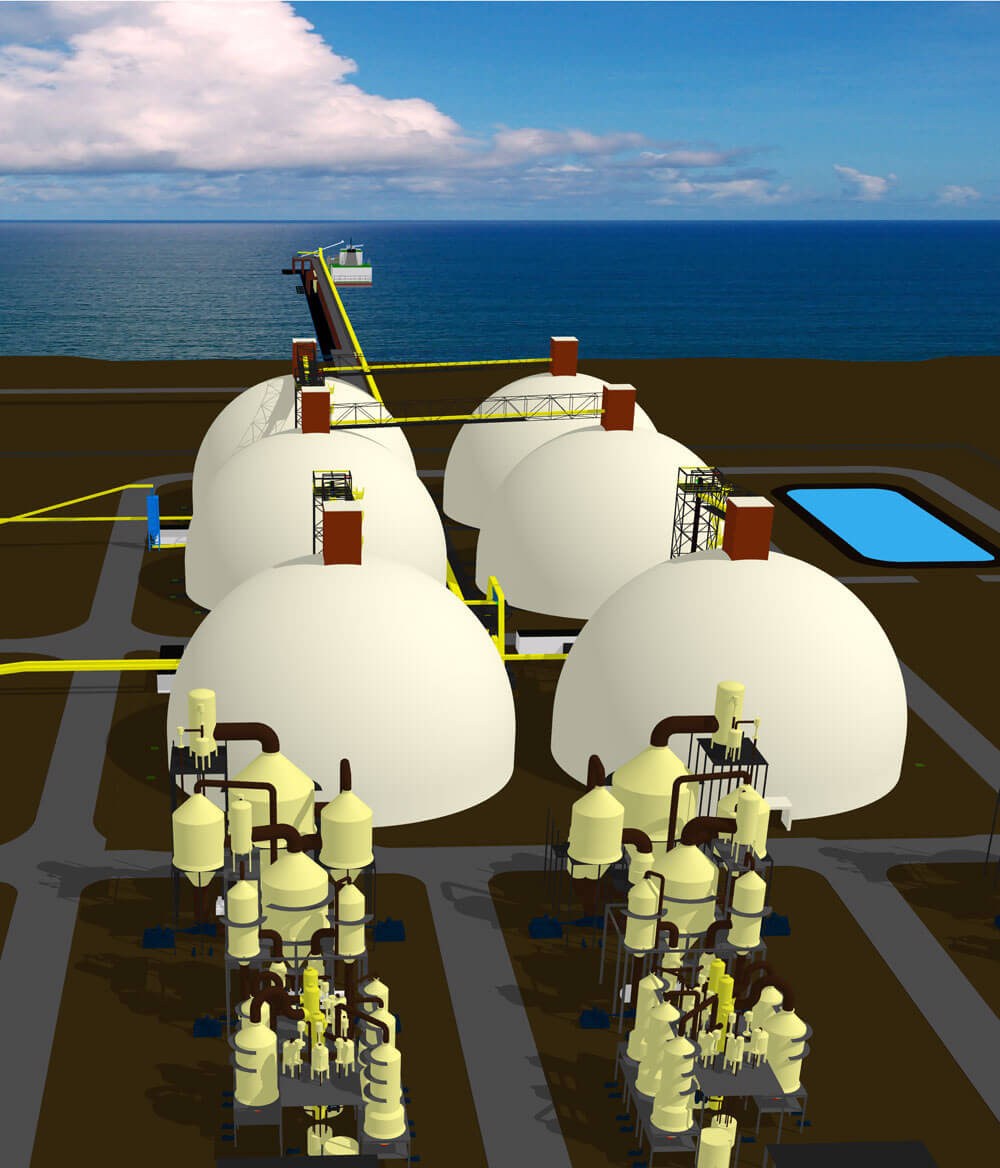

Sedgman Novopro has acquired the knowledge and expertise necessary to deliver multiple storage solutions including steel or concrete silos, monolithic concrete domes, sprung structures, or outdoor bulk storage designs, while minimizing risks and optimizing the selection of materials of construction, capital and operational cost expenditures.

During the course of executing scoping and feasibility studies, and detailed engineering, Sedgman Novopro have performed the following for Bulk Material Storage, Logistics & Material Handling Systems:

- Trade off studies for the selection of the optimum storage facility system among available options that best fits for the project’s needs

- Design services covering conceptual design works, basic engineering and detailed engineering works

- Preparation of request for quotation (RFQ) packages for equipment suppliers and construction contractors, and interfacing with the suppliers, contractors for the estimation of CAPEX and OPEX expenditures for such projects as well as for construction purposes

- Automated loading and unloading systems designed for transport truck or railcar fleet

Tailored storage solutions imply equally tailored auxiliary systems for bulks feed and reclaim. Depending what the project’s needs are, such systems may include provisions for, either, “manual” or automated reclaiming. Product integrity preservation permitting it, manual reclaim using suitable vehicles may offer a cost effective option. Where such approach is not possible, several automated systems are available for implementation. They typically consist of mechanical stackers/reclaimers or gravity fed underground network of conveyors. Sedgman Novopro’s know-how provides flexibility in selecting the most adapted solution.

Logistics

Sedgman Novopro understands the importance of efficiency and compliance to in-country road transportation regulations. Sedgman Novopro’s involvement in numerous projects has provided the team with the skills necessary to conduct logistical studies and deliver comprehensive product logistics solutions tailored for each application.

- Analysis on market demand and seasonality on storage requirements both in plant and other strategic locations

- Transport truck and train loading systems

- Train spur line design including bulk terminal loading and unloading system

- Dynamic simulation of material supply to model materials logistics and identify storage and loading/unloading requirements

- Trans loading systems for moving product from truck to train

- Trans loading systems for moving product from barge to ocean vessels, used where deep-sea harbours are not available

- Medium to high capacity ship loader design

Power Generation

Power Generation is a crucial component for all projects. The development of this sector involves vigilance towards a projects’ location and environmental considerations. Sedgman Novopro has delivered complete design and estimates for Gas Turbine Power Plants, Co-Generation Power Plants as well as Primary/Secondary O/H Power Lines.

For more remote locations, diesel power generation is sometimes the most economic option and for isolated equipment with lower power consumptions, solar power can be the best.

Sedgman Novopro incorporates aggregates the energy consumption rates and the associated costs into the financial models to understand the long term effects of the selected power generation technologies and mitigate the risks and find opportunities.

Water Supply

Having designed projects in some of the most arid regions in the world, Sedgman Novopro has gained a critical approach to water consumption in the design. Sedgman Novopro has conducted field drillings and pumping tests during hydrological studies for various projects to understand the water resources and adapt the process considering the local water composition and availability.

Heat Management Systems

Sedgman Novopro understands the technical and commercial impacts of an inefficient heat management plan, and the impact on both the Capex and the Opex . As a result, Sedgman Novopro has concentrated on providing fully integrated and optimized systems, by considering all project areas from the resource right up to the plant output by performing a pinch analysis, and integrating opportunities for heat recovery and energy transfer. As a number of mineral processing facilities require both process heating and process cooling, Sedgman Novopro has developed unique designs and equipment selections for the unit operations, where the heat extracted from a cooling application is recovered to unit operations and areas where heating is required. This configuration not only recovers the process heat from a unit operation, but also recovers the energy from the large motors providing the cooling while minimizing the volume of water required for the process.