- Expertise

- PONDS

Novel Simulation Using Pond Modelling With Proven Results

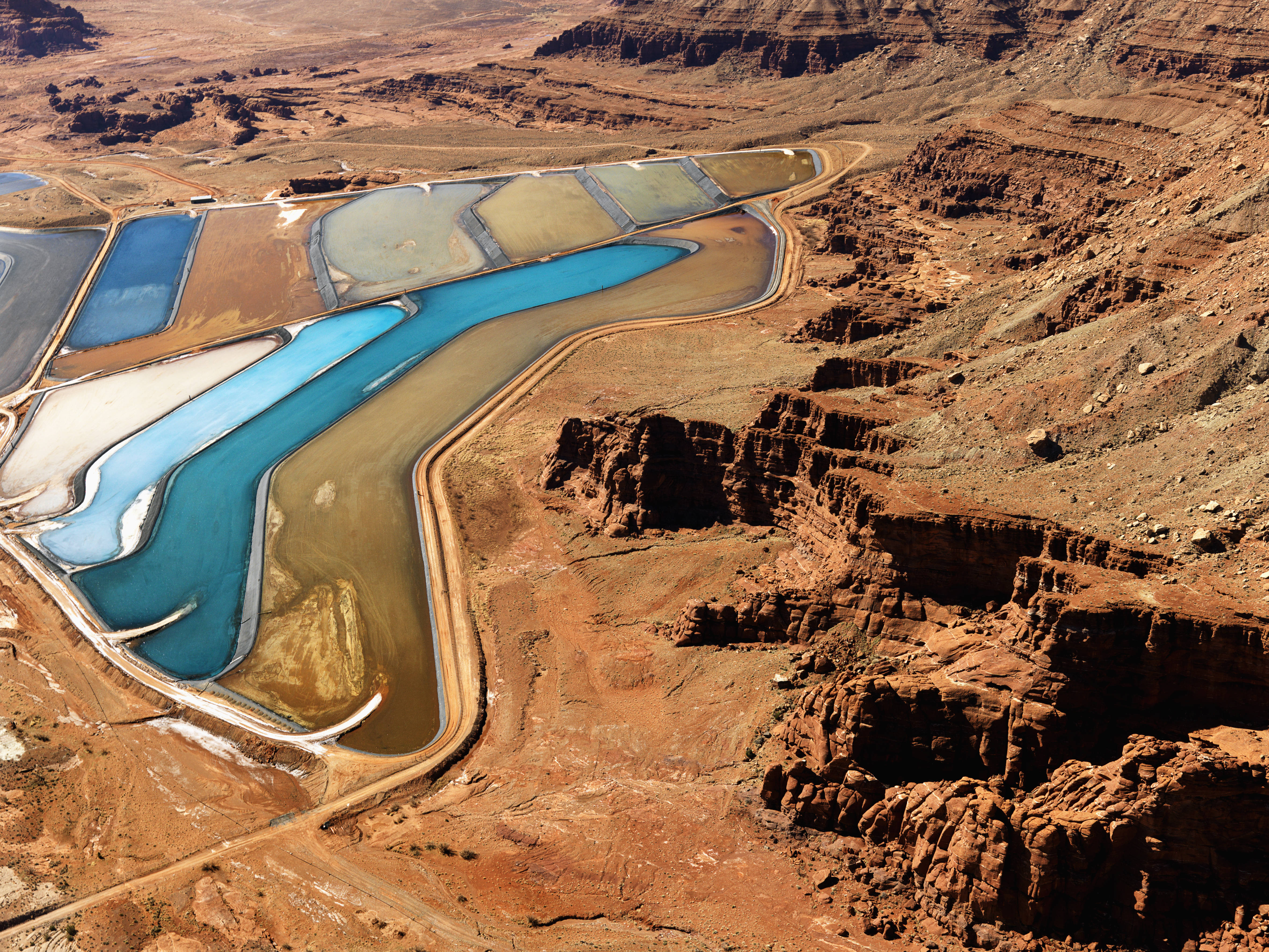

Evaporation and crystallization ponds generate intermediate products from a range of ore recovery methods such as waste brine streams, solution mining brine recovery wells and brine recovery canals.

Sedgman Novopro has considerable experience with pond investigations and design in North America, the Middle East, Africa, Asia and Australia. Every pond system is unique, with specific climatic and environmental conditions used as key drivers for pond design, modelling and optimization.

Sedgman Novopro’s pond expertise for conceptual design and existing operations include:

Pond Design

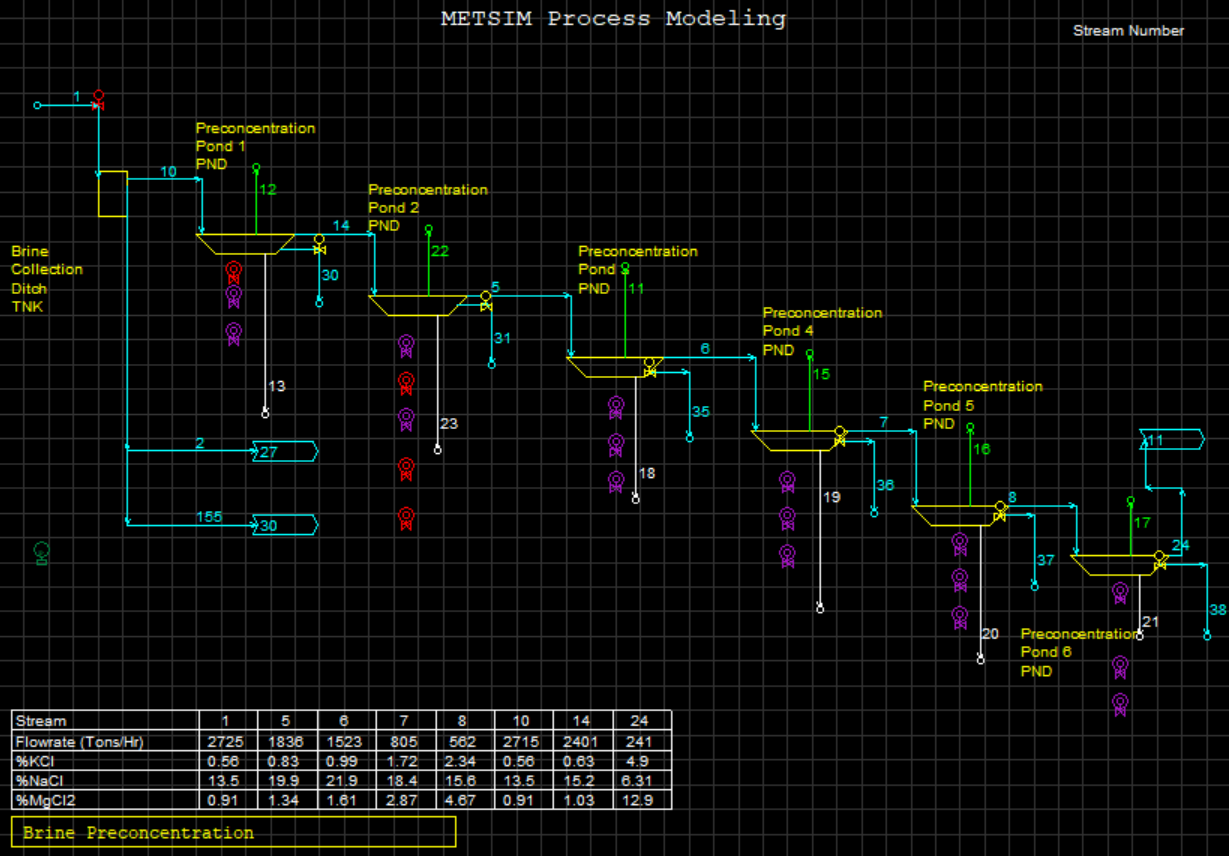

Sedgman Novopro’s methodical approach commences with a compilation of all available environmental and weather data and reviewing the projected brine composition. An initial pond model is then developed using PHREEQC and METSIM modelling software. Subsequent model iterations are then generated as the pond design is optimized by introducing recycle streams from the processing plant itself, and/or the pond end brine.

- Evaporation Rate

- Rainfall events

- Seasonality

- Deposition Rate

- Species of minerals deposited

- Brine entrainment with the precipitated salts

- Soil permeability and brine lost from un-lined ponds

- Area topography

- Pond Area Contingency

- Storage / Buffer Capacity

The following are the main pond design considerations:

Pond Modelling

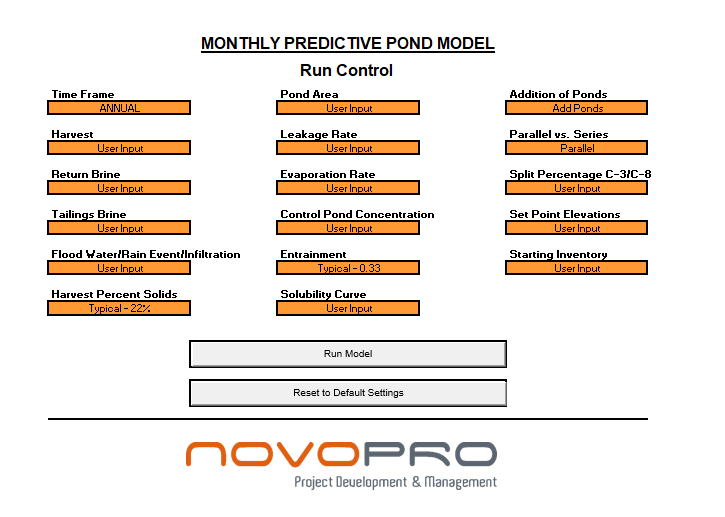

Pioneer in Pond Modelling Pond systems are specific to each application due to the variance in material balance properties such as feed brine composition, evaporation rates, leakage rates, brine entrainment and brine solubility equations. Sedgman Novopro has developed a comprehensive pond model that can be adapted to fit any brine system in the world. The model’s quick simulation capability facilitates the optimization of pond arrangement and operation.

Knowledge, Experience and ConfidenceSedgman Novopro’s pond model is a versatile tool for pond development and optimization in both the early stages as well as operations. The model can be configured based on user data to determine the pond areas for use in the early stages. Similarly, the model can assign data from operating ponds to troubleshoot and optimize existing systems.

Accuracy, Adaptability, Efficiency and OptimizationThe effect of changing seasons on a pond system can be simulated by running monthly iterations of Sedgman Novopro’s model to generate a summarized annual output. Sedgman Novopro can test numerous conditions within a matter of minutes when searching for issues and optimization opportunities. Assumptions can be defined within the model for special cases such as a system susceptible to major flood events.

Proven resultsSedgman Novopro has developed pond models for multiple commercial pond operations. The simulation outputs were matched to the actual operating data, thus validating the accuracy of the models. Arab Potash Corporation of Jordan and Compass Minerals of Utah, amongst others, have integrated Sedgman Novopro’s pond model into their operations.

Pilot Pond Programs

Sedgman Novopro has developed, coordinated and managed a multitude of Pilot Pond testwork programs specifically tailored to the needs and objectives of the project. Pilot ponds can be used to produce representative raw salts from the source brine to confirm evaporation rates, provide equilibrium and kinetic data, and gather data for pond start-up modelling. The raw salts harvested from Pilot ponds are often used as feed material for subsequent process testwork programs.

- Pilot pond construction designs including pond size, configuration and materials required

- Pilot ponds test plans, including sampling frequency, sampling methods, brine transfer methods and frequency, harvesting methodology and data recording templates

- Pilot pond operation model to determine weekly/daily flow schedules

- Support during the operation of the pilot ponds, including review of the analytical results of the brine samples, development of the brine concentration path chart, and advance notice of brine transfers

- Interpretation of the analytical results of the harvested salts

- Final report on the quantity, quality and species of salts produced as compared to the design

Sedgman Novopro has provided the following:

Pond Optimization

Sedgman Novopro can perform comprehensive reviews and analyses of existing pond operations to identify areas where potential resource losses may be occurring, or where topography may be causing losses in effective pond area. Sedgman Novopro’s recommended technical and financial alternatives are then presented with justifications and back-up. The execution of laboratory or pilot scale test programs may also be recommended to evaluate the feasibility of the selected option.

- Establishing pond floor seepage rate and lateral seepage rates

- Identification of seepage reduction and mitigation strategies

- Integration of topography data into GIS models for pond configuration

- Pond segmentation to maximize the use of natural topography to assist in inter-pond brine transfers

- Impact of topography and salts buckling on the reduction of effective pond area

- Optimization of ponds cut-off points and chemistry to produce high grade potassium salts

- Mitigation of entrainment brine losses

- Berm failure prevention

- Brine transfer pump station optimization

Typical areas targeted during pond optimization include the following:

Brine Transfer

Sedgman Novopro’s brine transfer solutions are configured to the specific brine volumes, concentration and composition of the system.

- Transfer pumps

- Weir Design

- Brine transfer over long distances

Pond Operations

Sedgman Novopro’s wealth of experience in both start-up and operation strategies for pond systems include brine transfer schedules based on the concentration in each pond, implementation of pond weirs, methods of maintaining uniform salt floors, tailings management, and equipment maintenance in a salt environment.Sedgman Novopro develops detailed pond start-up models and programs for determining start-up timelines, requirements for building a halite base in the harvesting ponds, production impacts of integrating additional ponds to existing operations.

- Feed brine modelling based on target production

- Pond start-up, ramp-up and operating programs

- Operating Philosophy

- Detailed brine monitoring, back-mixing and transfer timing

- Recommended brine operating levels and transfer methods

- Tailings management options: berms raising vs salts harvesting

- Brine transfer equipment, performance and maintenance strategies

- Pond harvesting strategy and recommended equipment

- Equipment maintenance programs

Additional pond operation expertise include:

Pond Harvesting

Harvesting and transport of precipitated salts are equally as important as the upstream brine handling and concentration processes. Sedgman Novopro’s detailed harvesting and transport analyses that typically focus on the tonnage of salt precipitated, variations in both the quantity and quality of salts precipitated at various periods during the evaporation season and the type of equipment most suited to handle the amount of material. The analysis will also look at the impact of harvesting operation on the required pond effective area, pond operating levels and stockpile requirements.

- Seasonal variation of precipitated salt quality and quantity

- Trade-off between dry harvesting vs dredging

- Pond de-watering and de-brining Methodology

- Harvesting Methodology

- Annual and seasonal harvesting schedule

- Selection of mobile equipment for harvesting and transport of salts

- Shutdown area for harvesting

- Interim crude salt stockpile design and recommended volumes

Key factors that influence the harvesting and transport strategies typically include: