- Projects

- BASE AND PRECIOUS METALS

Sedgman Novopro has been involved in multiple Base and Precious Metals projects. From extraction to crushing, preliminary processing and concentration all the way to final product, the Sedgman Novopro team has gained experience through the development of multiple projects. Testwork confirmation and process design are integral to the method used for project design and implementation. The team’s experience and know-how allow Sedgman Novopro to bring value to clients throughout the world. Related Projects

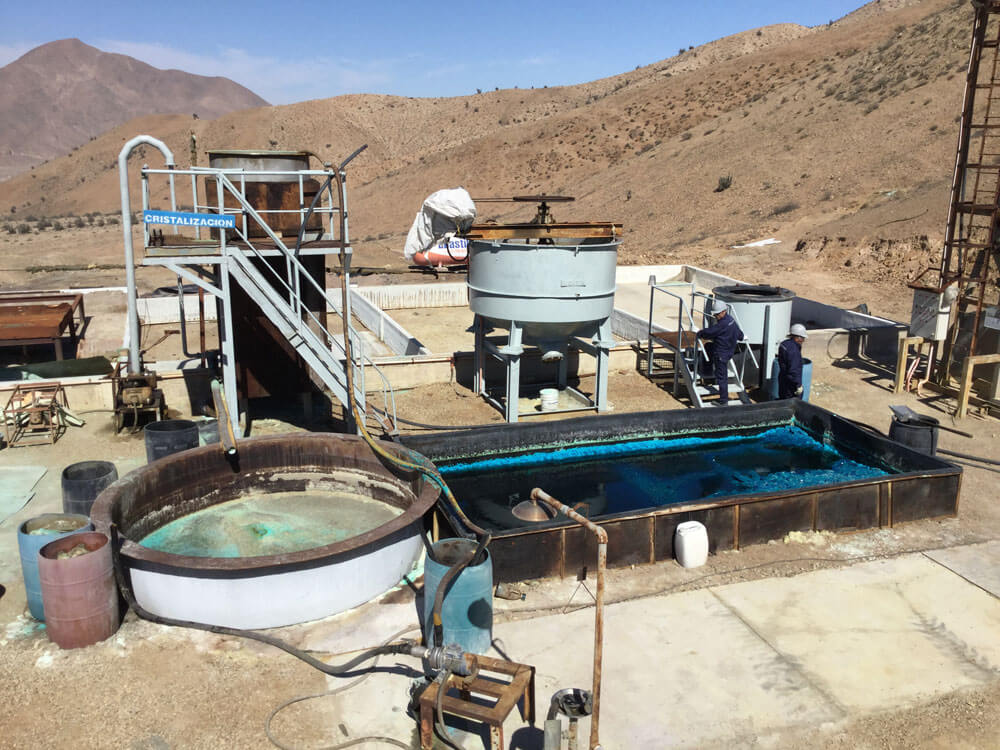

GMH Copper Processing Facility Quadra Mining Corp.

Quadra Mining Corp (Quadra) and its partner Gareste Ltda in Northern Chile possess an existing small copper processing facility named the GMH Plant. The GMH Plant is located 12 km South of Copiapo, and was constructed and started up in 2006, and operated until 2009 at which point it was mothballed due to low base metal prices and a business slow down.

NOVOPRO was mandated by to prepare an Engineering Assessment and Investigation report on the present state of the GMH processing facility, based on the following:

- Confirmation of the Capital Cost Estimate in order to bring the plant to an operational state at the nameplate rating of 600 tonnes of Copper Sulfate Crystals per year, and to increase to 1,200 tonnes per year

- Assessment of the process requirements to include the processing of a mineral rich dust feed stream from a state-owned copper producer (ENAMI)

- Investigation of the existing Electrowinning section

Bongará Zinc-Oxide Zinc One

The Bongará Zinc-Oxide Project located in the Amazonas Department of NorthCentral Peru. Bongará is a Mississippi Valley Type (MVT) base metal deposit characterized by high-grade zinc with associated lead and silver mineralization that is potentially at or close to the surface.

NOVOPRO’s mandate involved the following:

- Desktop trade-off study to evaluate Pyrometallurgical and Hydrometallurgical processing methods, utilizing all existing data and reports, and taking into account the existing site constraints.

- Coordination and execution of the Metallurgical Testing Program on selected core material recovered from the site by the geologist for the selected processing routes.

- Preparation of a document outlining the preferred processing route followed by the Process design including Block Diagrams and Mass, Heat and Water Balances.

Buhemba Gold Project Minmet Financing

The Buhemba Gold Project is located 150 km north‐east of the regional town of Mwanza, Tanzania, in the Lake Victoria’s goldfields. The Project has carried out a new estimate of its geological resource and mining inventory.

NOVOPRO was mandated by ARETHUSE Geology to review and optimize the Buhemba Gold 3,000 tpd carbon-in-leach (CIL) Plant design. As part of the mandate, NOVOPRO provided improvements and optimizations to the overall process and multi-disciplinary design as suggested by EPC contractor for use in the Project.

This work consisted of the following activities:

- Review of the process flowsheets

- Review of the process design, including the unit operations and equipment selection based upon the critical operating parameters impacting the gold recovery and productivity of the plant

- Modification and optimization of the process design to reduce both theproject cost and risk

- Review of all engineering discipline designs

- Review and optimization of the plant layout suitable to site conditions

- Review of utility requirements including water balance

- Review of the CAPEX and OPEX